Inventory management is the process of having the right products, in the right quantities, at the right time to sell to customers. Accurately managing inventory can increase revenue by preventing stockouts, excess inventory, and unsold products. When learning how to organize inventory for small businesses, the easiest solution is to use a software program to automate the process.

We recommend using an ERP system like Bisync to automate your inventory management procedures. It will streamline your inventory management processes, save you time, ensure accurate and up-to-date records, and provide reports and insights to help you understand your bottom line.

Step 1: Organize Product & Vendor Information

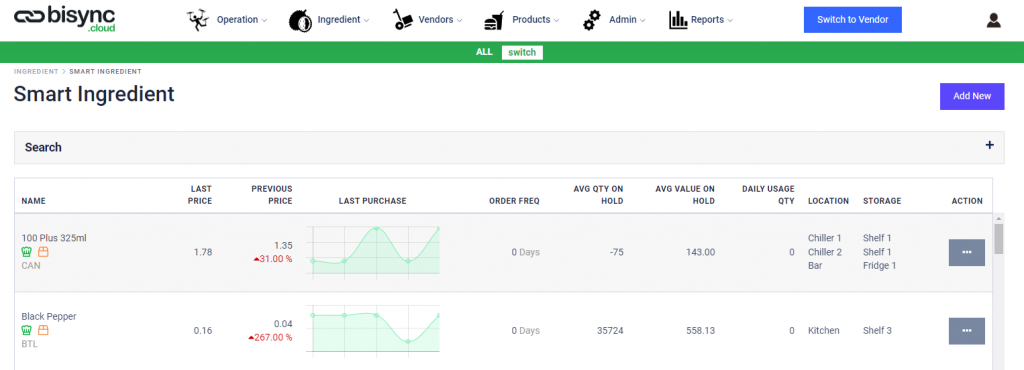

The first step in organizing your inventory is to set up your stock and supplier information in a reliable and accessible system. Some businesses use manual tracking methods such as spreadsheets. However, the best option for restaurant operators and retailers is to Bisync that is synced to your point-of-sale (POS) system. With the integration, Bisync can help you keep a vendor directory with searchable product for you.

To organize your inventory, you’ll first need to record information about each item and upload it into our system, from there, Bisync will basically work behind the scene keeping your inventory intact and keep you updated when an item is reaching your PAR level.

Build Relationships With Product Suppliers

Even with the best inventory management plan, issues can still arise where you need products ASAP to fulfill an order. When this happens, operators are at the mercy of their suppliers. If there is a quality control issue or a discrepancy with a purchase order (PO), having a good relationship with your supplier can help resolve these issues quickly.

Retail and F&B businesses can build strong relationships with product suppliers by sticking with the same suppliers over a period, meeting suppliers in person at trade shows, and, perhaps most importantly, paying invoices on time.

Step 2: Create & Submit Accurate Purchase Orders

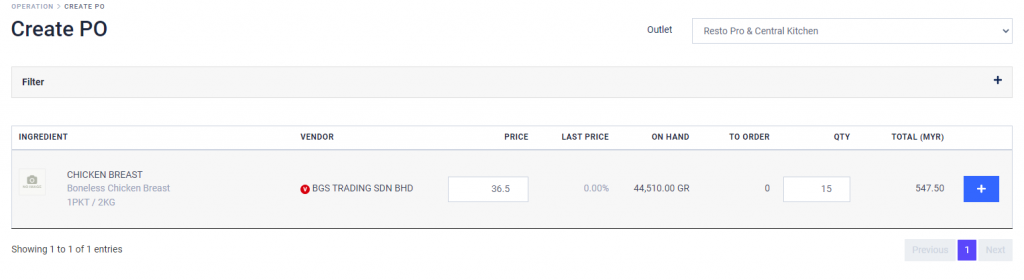

Essentially, POs are buyer-created receipts that document the sale of products to be delivered on a future date. They are the easiest way to manage your inventory purchases, letting you track every stock purchase efficiently, from placing the order to receiving the shipment and paying the bill. POs are financial transactions, so Bisync has been designed to assist you in creating the most accurate and detailed POs to keep your business running smoothly.

Bisync helps you to keep track of your POs so you have a record of everything you purchased from your supplier and can cross-reference your deliveries with what you actually expected to receive. This will help you stay on top of your inventory counts and prevent shrinkage.

For example, say I want to order 300 pieces of chicken breast from my favorite supplier for this coming week. I just select the item I want to buy from the supplier of my choice using the app, Bisync automatically calculates the total price base on your input and submit my PO to the supplier with a delivery date. Then, when my orders get delivered, I can use Bisync to make check and consolidate the orders easily on receiving.

Purchase orders are typically submitted to vendors electronically through whatsapp or email or fax based on the details that vendors provide. With the PO function, you can easily share, download and print the purchase order easily on both desktop and mobile app.

As mentioned before, through integration with POS systems, Bisync will give you a low-stock alerts that tell you when an inventory item reaches a designated minimum threshold and when you need to place a new PO. This will help you prevent stockouts and the accompanying disappointed customer.

Step 3: Receive Inventory Orders Accurately

Once you have submitted your purchase order for the right amount of stock, you want to be sure that you receive that stock accurately. Supplier errors happen often, and if you aren’t being diligent about systematically receiving your inventory, you might get shorted, overcount, or underestimate your inventory levels—which can lead to shrinkage and a decrease in your margins.

To receive inventory correctly, companies should receive and unpack all boxes in the same space, count each box, and check the items received against original purchase orders.

It’s especially important to ensure that you check all received items against your PO. Suppliers generally include packing slips that list the items and quantities in your shipment. While this slip will likely match the physical shipment, if the supplier made an error during order entry, the packing slip would not match your PO, and the quantities would not be accurate.

If you do not catch order discrepancies by checking the received items against your PO, you run the risk of thinking that you received stock that didn’t actually arrive. That leads to stock shortages, backorders, and, ultimately, cash losses.

How to Accurately Receive Stock Shipments

- Unpack the shipment and organize items by product.

- Load the PO in the Bisync app to cross reference the quantity you input and the amount received.

- If the counts and products match, consolidate the PO accordingly.

- If you find errors like wrong, shorted, or missing items, note these on your PO in-app and contact your supplier immediately to resolve them.

- Shelve or store all correctly received stock (Bisync will automatically add the details into the system upon consolidation).

- Enter your bill into your accounting system.

Step 4: Organize Your Stockroom or Warehouse

Having an organized stockroom will not only make things easier to find for you and your employees, but it will also allow you to fit more inventory and keep better tabs on the inventory you already have.

In any conventional outlets, all storage shelves and racks should be labeled to help you find what you need efficiently.

Whatever your inventory storage method, your stored inventory needs to be well-organized, clearly labeled, and accessible for pulling and inventory counts. This can be done using the boxes goods come in, stacking bins, or even hanging separators for hung apparel.

In Bisync, we designed the system to help you create storage locations in-app, this is designed so that you can easily do your inventory count base on each locations and not rummaging through a big list of inventory just to do a spot count.

Step 5: Track Inventory in Real Time

Tracking your inventory levels in real time is key for keeping the right items on the shelves in the right quantities—i.e., good inventory management. Integration with a POS allows Bisync to help you adjust your inventory level base on your daily sales.

Bisync is able to keep track real-time inventory levels and adjust your counts with every sale. As your inventory numbers dip below your safety stock level, you can set up reorder alerts or stockout warnings. Bisync will make tracking inventory levels and reordering your supplies quick and easy and, most importantly, base your inventory on actual sales trends, not on your best guess.

Step 6: Conduct Regular Inventory Counts

Physical inventory counts can be mundane and tedious. However, physical counts can reduce all types of inventory problems dramatically. Most small businesses do a full inventory count once each year for tax purposes, but it’s good to perform smaller partial inventory counts, or cycle counts, even if you are using Bisync to deplete your sold inventory.

Quantity on Hand

The basis of both annual and cycle inventory counts is your current Quantity on Hand (QOH) or the amount of inventory you should have in stock for every item you carry. The formula for QOH is as follows:

QOH = (Previous QOH + Received Inventory)-Sold Inventory

Your QOH is the number that you will measure your annual and cycle counts against. So, for example, if I thought I should have 272 packs of gum based on my QOH calculation, I would be looking for 272 packs of gum in my cycle or annual count. If I found a discrepancy, say only 250 packs of gum, that would indicate an error or theft that I could then look into further.

Annual Inventory Counts

Annual inventory counts are a complete inventory count, typically done at the close of each fiscal year for income tax purposes. These counts give you an overall picture of how much inventory you have on hand at the close of your year. Annual inventory counts can also help businesses uncover inventory shortages due to miscounts, shrinkage issues, misplaced stock, and/or receiving errors.

While most retailers perform more frequent counts, some small businesses with limited staff or small inventories will only perform this type of inventory count each year. While annual inventory counts are a good practice regardless, by year’s end, it’s too late to fix most of the problems they reveal. To catch inventory issues before they become costly, you’ll also want to conduct periodic counts, called cycle counts.

Cycle Counts

Cycle counts are periodic spot counts that take inventory of specific categories or subsets of products. Typically, you perform cycle counts regularly. So you might decide to count certain groups of inventory every other Wednesday and some groups every two months. As a best practice, you would cycle count all of your products daily to keep a good grasp on their levels. Without the right tech and staff, however, this is next to impossible. Schedule your cycle counts based on the speed with which you move through your inventory, with items that sell faster getting more frequent counts.

Manual or Automated Counting

When it comes to how you count your inventory, you have two options. You can either do it manually or use a system like Bisync to automate your processes. Here, we will look at both manual and automated inventory management options and how they both can work for your business.

Manual Counting

While we would suggest using a digitized system to count your inventory for you, if you do decide to go the manual route, your first step will be tallying your QOH based on your POs, last year’s inventory, and a sales tally of each item sold. From there, you’ll need to create inventory count sheets to record your physical counts and begin counting.

While you can do it, manual counts are less accurate and more time-consuming than your automated ERP option.

Automated ERP Counting

While Bisync can’t count all the physical items in your inventory, it can place live QOH counts and inventory lists at the tips of your fingers to help accelerate and streamline your inventory counts. We suggest using a system like Bisync to help eliminate errors in your inventory management and make your business more efficient.

If you do decide to go with an inventory system to count and track your inventory, we recommend Bisync. It keeps live QOH counts as you receive and sell items, continuously tracks your inventory levels, alerts you to low stock items, and provides reports and data to help you better understand and manage your inventory.

Step 7: Reconcile Discrepancies

Ideally, your physical inventory counts will match your projected QOHs. However, that is not always the case. If you have more or less of a product than anticipated, you will need to investigate the problem and reconcile the difference. In a typical operation, this difference is known as a variance.

There are two primary reasons that inventory shrinkage occurs. Either there has been a clerical error or theft has occurred. Sometimes, clerical errors are not actual losses—an item could have been misplaced or a key mistyped. Other times, shrinkage indicates actual loss and you should investigate where it happened so you can work on preventing it in the future.

If you determine that your missing merchandise is truly gone, you should adjust your QOH in your records. After that, you need to record the dollar value lost due to the shrink in your inventory.

Bottom Line

A good inventory management system means that you always have an accurate picture of your stock so that you can avoid waste and provide the merchandise and experience that your customers expect. Whether you’re looking to learn the basics of how to organize inventory for small businesses or reinvigorate an existing system that has become disorganized, these steps will help you set up and streamline your operations.

If you would like to know more about Bisync, drop us a mail at sales@cubevalue.com and our team will get in touch with you.